© Henan Guoxin Machinery Manufacturing Co., Ltd. All Rights Reserved.

Introduction of freeze-drying equipment freeze-drying equipment Freeze-drying equipment technology was used as early as World War II for the preservation and production of biological products s...

freeze-drying equipment

Freeze-drying equipment technology was used as early as World War II for the preservation and production of biological products such as plasma, antibiotics, and bacteria. When needed on the battlefield, dried products could be revived by adding physiological saline. After the war, it was mainly used for the production of biological products and pharmaceuticals.

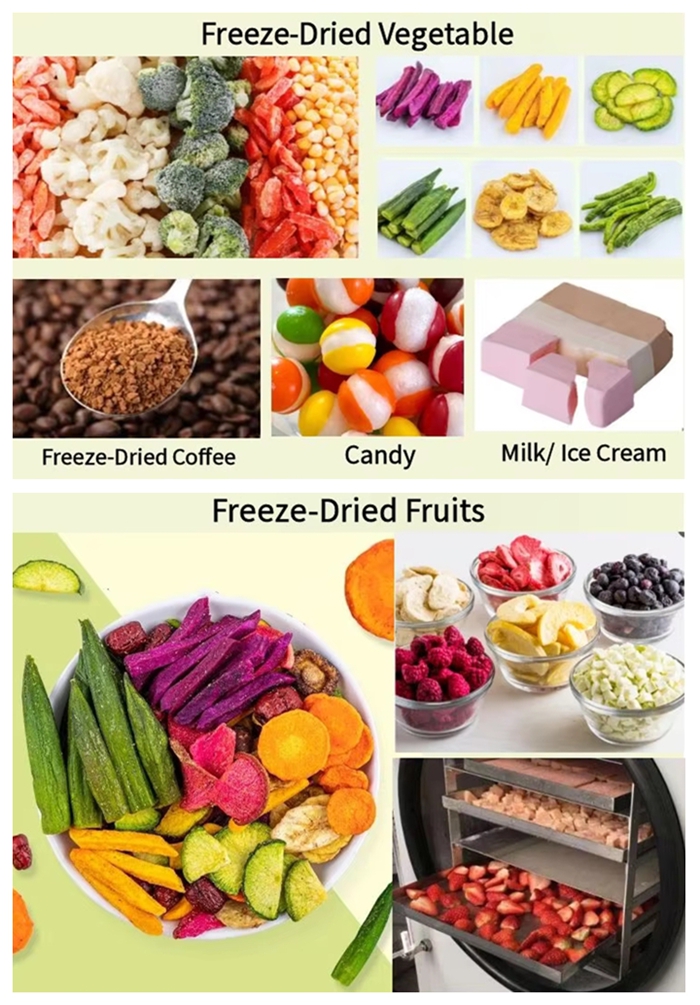

In recent years, freeze-drying technology has begun to be applied in the food and traditional Chinese medicine processing fields.

Its characteristics of preserving the color, shape, nutritional (medicinal) components of raw materials, as well as its crisp texture, easy rehydration and dissolution, and ease of preservation, have shown great application potential in this field, attracting widespread attention from industry professionals.

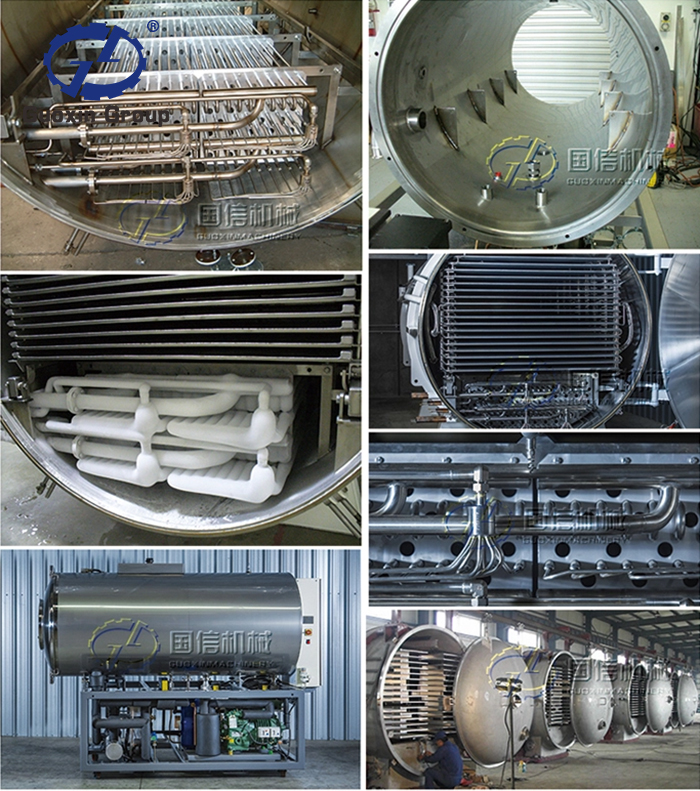

Vacuum freeze-drying equipment is a state-of-the-art dehydration method that pre-freezes water-containing materials at low temperatures, then heats them under low-temperature vacuum conditions, causing the fine ice crystals frozen in the material to sublimate directly and be collected by a condenser, thus obtaining dry substances. This equipment is a comprehensive application of technologies integrating mechanics, refrigeration, vacuum, and electrical control.

Sublimation is a physical phenomenon. Ordinary water exists only in two states—ice and vapor—under a vacuum; liquid water does not exist. In this vacuum environment, water can only transform between these two states with temperature changes. Utilizing this principle, the material to be dried is pre-frozen and then placed in a vacuum environment with the temperature gradually increased. The ice in the material gradually sublimates into water vapor and leaves, ultimately leaving behind the dehydrated material. No liquid water is present during the drying process.

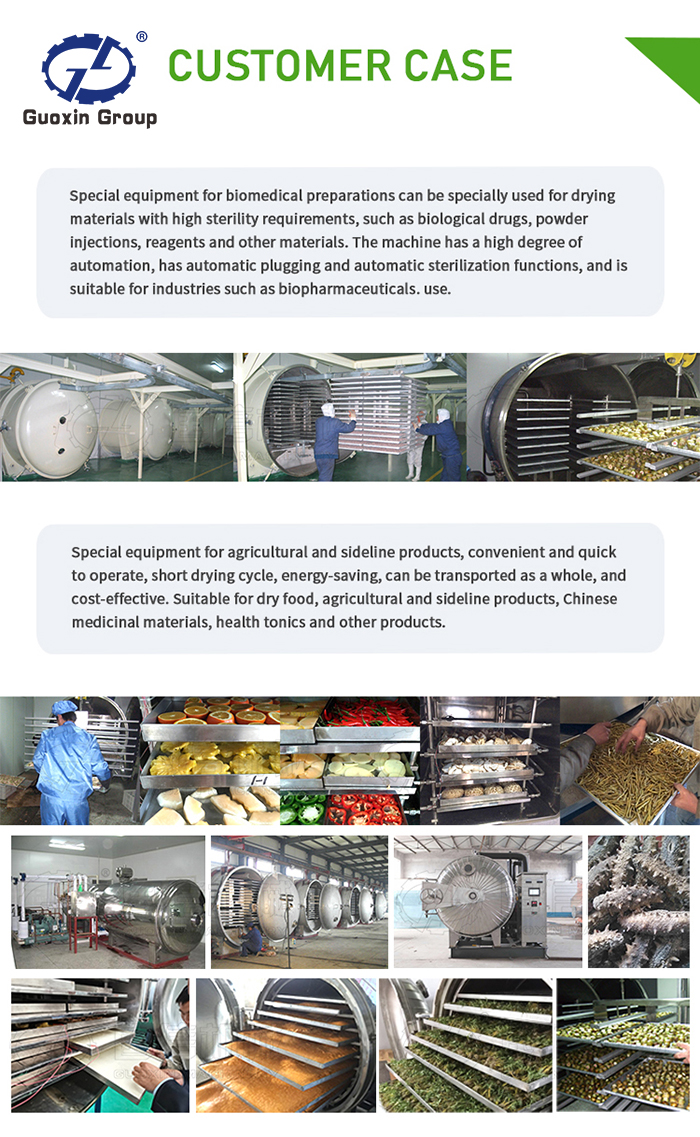

To meet the drying needs of different industries and materials, this equipment is divided into six major series based on application, drying object, drying scale, and method, to facilitate selection by users in various industries.

1. Freeze-drying Test Chamber

2. General-purpose Freeze Dryer

3. Continuous Freeze Dryer

4. Food Freeze Dryer

5. Pharmaceutical Freeze Dryer

6. Large-scale Freeze Dryer

The freeze-drying equipment, process is carried out in a completely isolated, low-temperature environment, free from airborne dust, bacteria, and other contaminants. The resulting dried product and raw materials remain virtually unchanged. Key advantages include:

1. Preserving the various components of the raw materials (including heat-sensitive, functional, and bioactive components);

2. Preserving the various properties of the raw materials (texture, appearance, color, taste, etc.);

3. Porous and crumbly, easy to pulverize and disperse;

4. Highly soluble in water, with rapid rehydration;

5. Thorough dehydration, easy for long-term storage and transportation;

6. Maintaining the original color, aroma, taste, shape, and freshness of the food.