© Henan Guoxin Machinery Manufacturing Co., Ltd. All Rights Reserved.

Need a Continuous Drying Solution for High Output? This mesh belt dryer has been applied in multiple food and agricultural drying projects, supporting continuous operation from 300 kg/h to several ton...

Need a Continuous Drying Solution for High Output?

This mesh belt dryer has been applied in multiple food and agricultural drying projects, supporting continuous operation from 300 kg/h to several tons per hour.

Share your material and capacity — our engineers will recommend a suitable configuration.

👉 Request a Technical Proposal

For industrial food processors requiring high output and continuous operation, batch drying systems are often inefficient and labor-intensive. A mesh belt dryer provides a stable and automated drying solution designed for large-scale production.

Our industrial mesh belt dryer is widely used for fruits, vegetables, spices,s and food materials that require continuous drying, uniform moisture removal, and reliable operation. The system can be customized according to material characteristics, capacity requirements,s and factory layout.

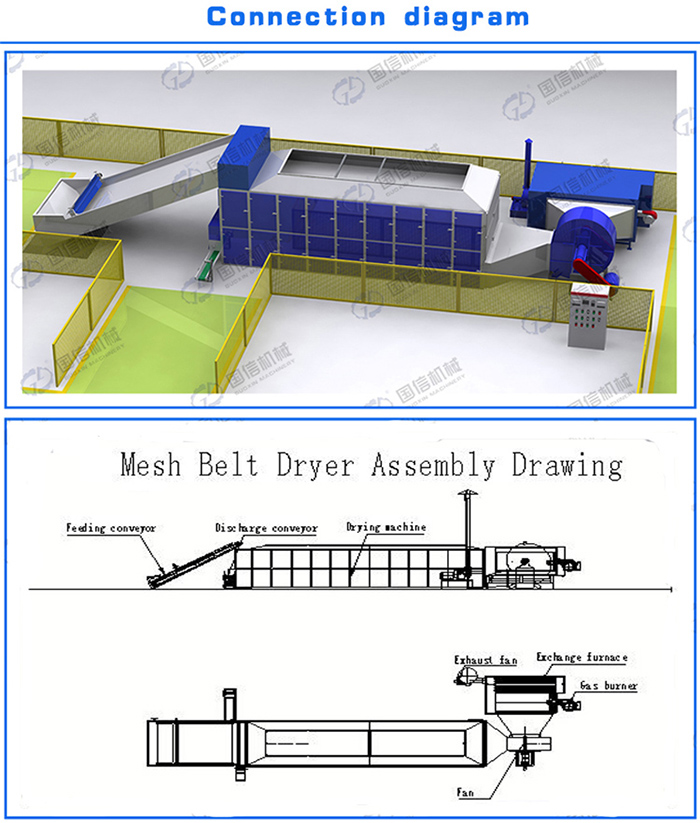

A mesh belt dryer uses a continuous conveyor belt system to transport materials through multiple drying zones. Hot air circulates evenly through the material layer, ensuring uniform drying while maintaining high throughput.

This drying method is especially suitable for sliced, diced, or granulated products that require continuous processing.

Feeding conveyor, discharging conveyor, mesh belt dryer main unit, dryer housing material, induced draft fan, indirect hot air furnace.

Continuous operation

Ideal for industrial-scale, non-stop production.

High drying capacity

Suitable for large-volume food processing plants.

Multi-zone temperature control

Different drying stages for optimal moisture removal.

Stable and reliable performance

Designed for long-term industrial operation.

Easy integration

Compatible with upstream slicing and downstream packaging equipment.

Mesh belt dryers are widely used for:

Chili slices and flakes

Ginger slices

Fruits and vegetables

Dehydrated food ingredients

Fruit & Vegetable Drying Solution

| System Type | Capacity Range |

|---|---|

| Single-layer Belt | 300–800 kg/h |

| Multi-layer Belt | 1–3 T/h |

| Customized Line | Up to 5 T/h |

Drying temperature, belt speed, and air circulation can be adjusted according to material requirements.

Widely used in vegetables, fruits, medicinal herbs, and food processing plants requiring continuous drying and stable output.

Not sure if this dryer fits your production line?

Share your material type, moisture content, and required capacity — we’ll confirm suitability before you invest.

> [Check Suitability with Our Engineers]

Compared with batch dryers, higher efficiency and lower labor costs

Compared with hot air tray dryers, more uniform drying

Compared with heat pump dryers, better suited for large-scale continuous production

Industrial-grade design for continuous operation

Customized drying zones and capacity

Integrated system solution capability

Reliable technical support and after-sales service

Need a high-capacity continuous drying system?

Contact us to get a customized mesh belt dryer solution for your production line.

Q1: What is a mesh belt furnace, and how does it work?

A1: A mesh belt furnace is a continuous drying system where food products move through a conveyor belt and are exposed to controlled temperatures and airflow. This ensures even drying and is ideal for large-scale production.

Q2: How can customizing a mesh belt furnace improve drying efficiency?

A2: Customization allows precise control over temperature, airflow, and drying time, making it easier to adapt the system for specific food types and maximize drying efficiency.

Q3: Can mesh belt dryers be used for different types of food?

A3: Yes, mesh belt dryers are versatile and can be used for fruits, vegetables, herbs, and even processed snacks like chips and pasta.

Q4: What is the drying time for food in a mesh belt furnace?

A4: Drying time varies depending on the food type, moisture content, and drying conditions. However, mesh belt dryers offer quicker drying times compared to traditional methods.

Need a customized mesh belt drying system?

Contact us for a free consultation and a tailored proposal.

Need reference projects or energy consumption data?

We can provide equipment layout, power consumption estimates, and similar project cases.

>[Ask for Project Reference]