© Henan Guoxin Machinery Manufacturing Co., Ltd. All Rights Reserved.

Paper tube dryer introduction The paper tube dryer(Heat Pump Drying Machine) is a kind of high-efficiency drying equipment specially used for paper tubes, paper barrels, and other produc...

Heat Pump Drying Machine

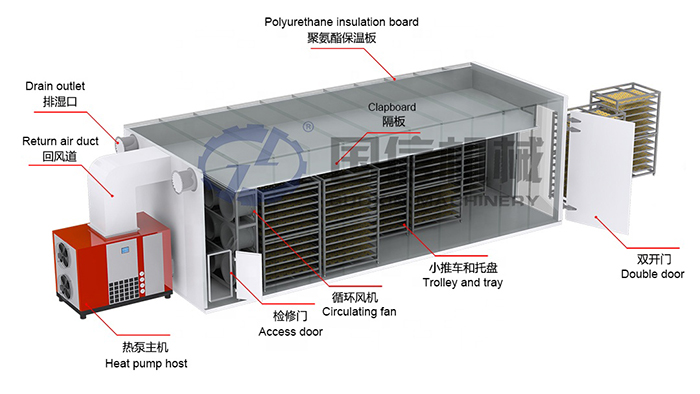

The paper tube dryer(Heat Pump Drying Machine) is a kind of high-efficiency drying equipment specially used for paper tubes, paper barrels, and other products. Our paper tube drying machine is widely used in packaging, printing, textile, papermaking, and industrial manufacturing. The paper tube drying machine uses hot air circulation or far-infrared heating technology through an intelligent temperature control system to evenly dry the paper tube in a short time, effectively remove moisture, improve the strength and durability of the paper tube, and avoid cracking, deformation, mildew, and other problems.

paper tube dryer

The paper tube drying machine adopts hot air circulation or far-infrared heating to evenly transport hot air to the drying room through the fan and heat source, so that the paper tube moves at a uniform speed on the conveyor belt or bracket, and is dried under controlled temperature and humidity. The equipment is equipped with an automatic control system that can adjust the temperature, air volume, and conveying speed to meet the drying needs of paper tubes of different specifications and thicknesses.

Heat Pump Drying Machine

Efficient drying: The hot air circulation system ensures that the paper tube is heated evenly, the drying speed is fast, and the efficiency is improved by more than 30%.

Intelligent temperature control: The PLC intelligent control system can accurately adjust the temperature and wind speed to prevent over-drying or local scorching.

Energy saving and environmental protection: Adopt a closed hot air circulation design to reduce energy consumption, reduce heat loss, and improve drying efficiency.

Wide range of applications: Suitable for drying paper tubes, paper barrels, and other products of different thicknesses and sizes.

Maintain the quality of paper tubes: Effectively avoid cracking, warping, and deformation of paper tubes during drying, and improve product stability.

Automatic operation: An optional automatic feeding and discharging system can reduce manual intervention and improve production efficiency.

Shorten drying time and improve production efficiency;

Intelligent operation and precise control of the drying process;

Energy saving and environmental protection, reduce energy consumption;

Maintain the shape and strength of paper tubes and improve product quality.

We provide comprehensive after-sales support, including equipment installation, operation training, regular maintenance, technical upgrades, etc., to ensure the efficient and stable operation of your paper tube dryer.