© Henan Guoxin Machinery Manufacturing Co., Ltd. All Rights Reserved.

Release time:2026-01-16

Choosing the right drying technology is critical for food processors. Different drying methods significantly impact product quality, energy consumption, and production costs. This guide compares three commonly used drying technologies to help manufacturers make informed decisions about their choices.

Working principle:

Hot air is blown across materials to evaporate moisture.

Advantages:

Simple structure

Low initial investment

Limitations:

High energy consumption

Difficult temperature control

Risk of color and nutrient loss

Suitable for:

Low-value, heat-resistant materials.

Heat Pump Dryer

Working principle:

Recycles heat in a closed system for low-temperature drying.

Advantages:

Excellent energy efficiency

Precise temperature control

High product quality

Suitable for:

Fruits, vegetables, spices, and medicinal herbs.

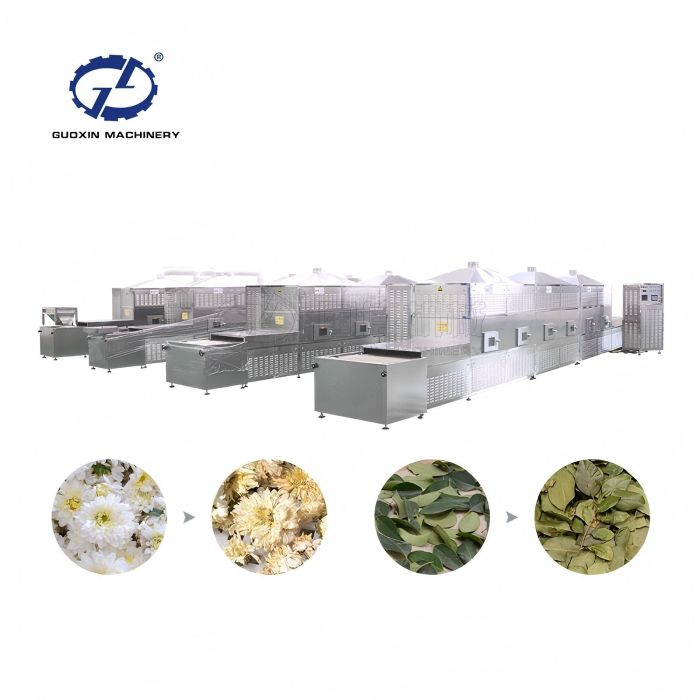

Microwave Dryer

Working principle:

Uses electromagnetic waves to heat moisture internally.

Advantages:

Swift drying

Sterilization effect

Limitations:

Higher equipment cost

Requires precise control

Suitable for:

Food sterilization, final moisture reduction.

| Technology | Energy Use | Product Quality | Speed |

|---|---|---|---|

| Hot Air | High | Medium | Medium |

| Heat Pump | Low | High | Medium |

| Microwave | Medium | High | Fast |

For premium quality → Heat Pump

For large-scale continuous drying → Mesh Belt

For fast drying & sterilization → Microwave

We also offer production line solutions:

Not sure which drying technology fits your product?

Contact us for a professional drying technology evaluation.